Coresix Processes

As a custom glass manufacturer, Coresix has quickly become a premier supplier of precision glass components to an array of markets. Early and continued success has driven steady growth, allowing Coresix to design and build a new facility suited to the needs of the customers we serve.

Coresix Precision Glass facilities are equipped with state-of-the-art custom CNC glass and glass component manufacturing equipment. Coresix Precision Glass has extensive experience in custom glass cutting and fabrication.

Our custom glass manufacturing services include custom glass cutting, glass edging, glass lapping, glass polishing, glass cleaning as well as laser marking glass, glass inspection, chemical strengthening glass, and custom packaging glass. To become a trusted glass supplier for markets all over the world, we have refined our process and perfected them. Allowing us to provide unmatched services for your business.

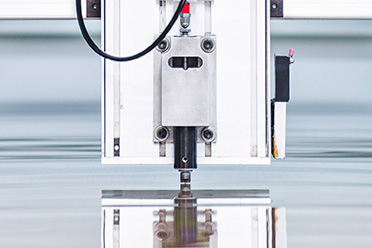

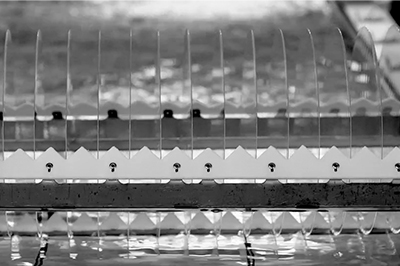

Glass Cutting

The introduction of materials into the Coresix glass fabrication process usually involves sizing the substrate for subsequent operations. This can be achieved by several means depending on the overall dimensions, thickness, and type of glass being used.

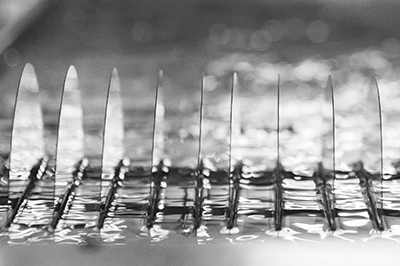

Glass Edging

At Coresix, we have the capability to apply the correct edge for every application and the knowledge to provide the most efficient and cost-effective solution to your glass needs.

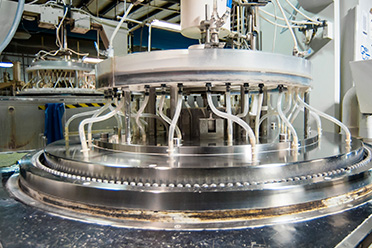

Glass Lapping

Our lapping and polishing experience dates to the late ‘70’s when flat substrates were required for mirror coatings used in copy machines and printing presses.

Glass Polishing

From a background in the mass production of CD Master Glass, Coresix has been successful in evolving our polishing process to produce the highest level of surface quality and cleanliness available in the semiconductor, photolithography, biotech, and display industries today.

Glass Laser Marking

Coresix has multiple UV and CO2 laser systems for the application of unique serialization to glass wafers. Our systems accommodate SEMI standards and custom parameters to precise locations. Once the laser mark is applied, the wafer is re-cleaned and inspected before final packaging. Wafer IDs can be applied to the label and data provided to each part.

Glass Cleaning

With many of today’s technologies, the introduction of foreign matter to the process can have a serious impact on production yields and product performance.

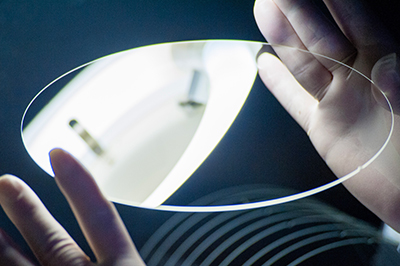

Glass Inspection

A surface imperfection not visible to the naked eye can become a glaring defect when magnified in the end product. A particle of glass, a fingerprint, or a water spot may go unnoticed until enhanced by the application of optical films.

Glass Packaging

From particle-free windows and wafers to large format, high volume sheet glass, Coresix has the experience and expertise to protect your investment through a variety of packaging solutions.

Glass Chemical Strengthening

Coresix performs chemical strengthening by inducing an exchange between the larger Potassium ions of the chemical bath and the smaller Sodium ions of the glass. The resulting compacted surface stress greatly increases the strength of the glass without optical distortion.