Lighting Conditions

Intensity: Coresix uses a standard “K Lux” to describe the required light intensity for a given inspection criterion. Any existing or known light intensity such as foot candle, wattage, etc., can generally be converted to a K Lux standard.

1.5K Lux

Identifies scratches beyond 60um wide and digs greater than 400um for low-end optical or high-end industrial applications.

5K Lux

Used to identify scratches beyond 40um wide and digs greater than 200um for common optical applications.

10K Lux

Identifies scratches beyond 20um wide and digs greater than 100um for high-end optical applications.

15-50 K Lux

Various collimated lighting is used to identify defects to 1um for critical optical applications.

Position

The angle, distance, and/or orientation of the glass being inspected to the light source.

Angle

The angle at which the part is held to the light source can influence the visibility of a defect. The specified angle may be driven by the final application (coatings to be applied, angle to be viewed, etc.) or to achieve maximum effectiveness. Unless otherwise specified, the angle will be defined by the standard of orientation.

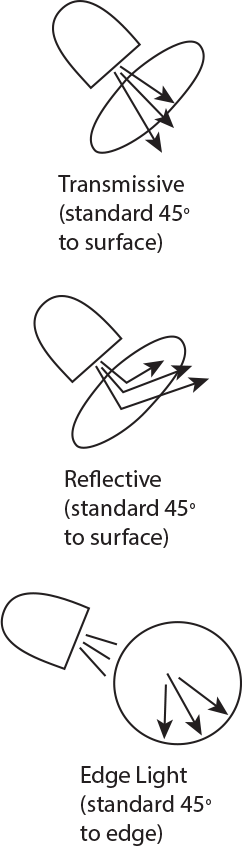

Orientation

The orientation of the part to the light source can influence the visibility of a defect. The specified orientation may be driven by the final application or to achieve maximum effectiveness. Unless otherwise specified, the standard orientation of inspection will be transmissive.

Distance

The distance of the glass from the light source is generally defined by the specified light intensity. However, under certain conditions, it may be necessary to specify the distance in conjunction with light intensity. If no specification is provided, distance from the light source will be defined by the specified light intensity.

Time

The longer an inspector looks at a glass component under any condition, the more likely he or she is to identify defects. For production efficiency, the specification is designed to identify the necessary cosmetic quality level in a minimal inspection time. Our standard inspection time averages 5-10 seconds per part.